Amafilimu ahlukahlukene avame ukusetshenziswa ekuphileni kwansuku zonke. Lawa mafilimu enziwe ngezinto ezinjani? Yiziphi izici zokusebenza zento ngayinye? Okulandelayo yisingeniso esiningiliziwe samafilimu epulasitiki avame ukusetshenziswa empilweni yansuku zonke:

Ifilimu yepulasitiki ifilimu eyenziwe nge-polyvinyl chloride, i-polyethylene, i-polypropylene, i-polystyrene namanye ama-resin, evame ukusetshenziselwa ukupakisha, ukwakhiwa, nanjengesendlalelo sokumboza, njll.

Ifilimu yepulasitiki ingahlukaniswa

-Ifilimu yezimboni: ifilimu evutheliwe, ifilimu enekhalenda, ifilimu eyeluliwe, ifilimu ephonsiwe, njll.;

- Ifilimu yeshedi yezolimo, ifilimu yemboza, njll.;

-Amafilimu okupakishwa (kuhlanganise namafilimu ayinhlanganisela yokupakishwa kwemithi, amafilimu ayinhlanganisela okufakwa kokudla, njll.).

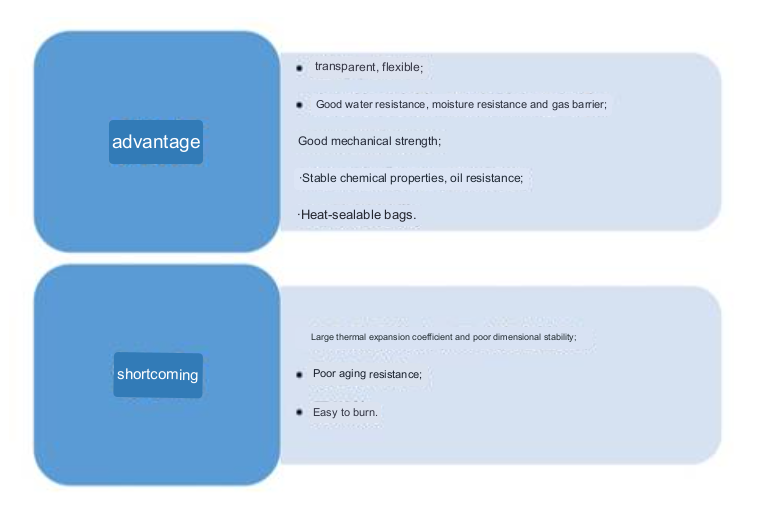

Izinzuzo kanye nokubi ifilimu plastic:

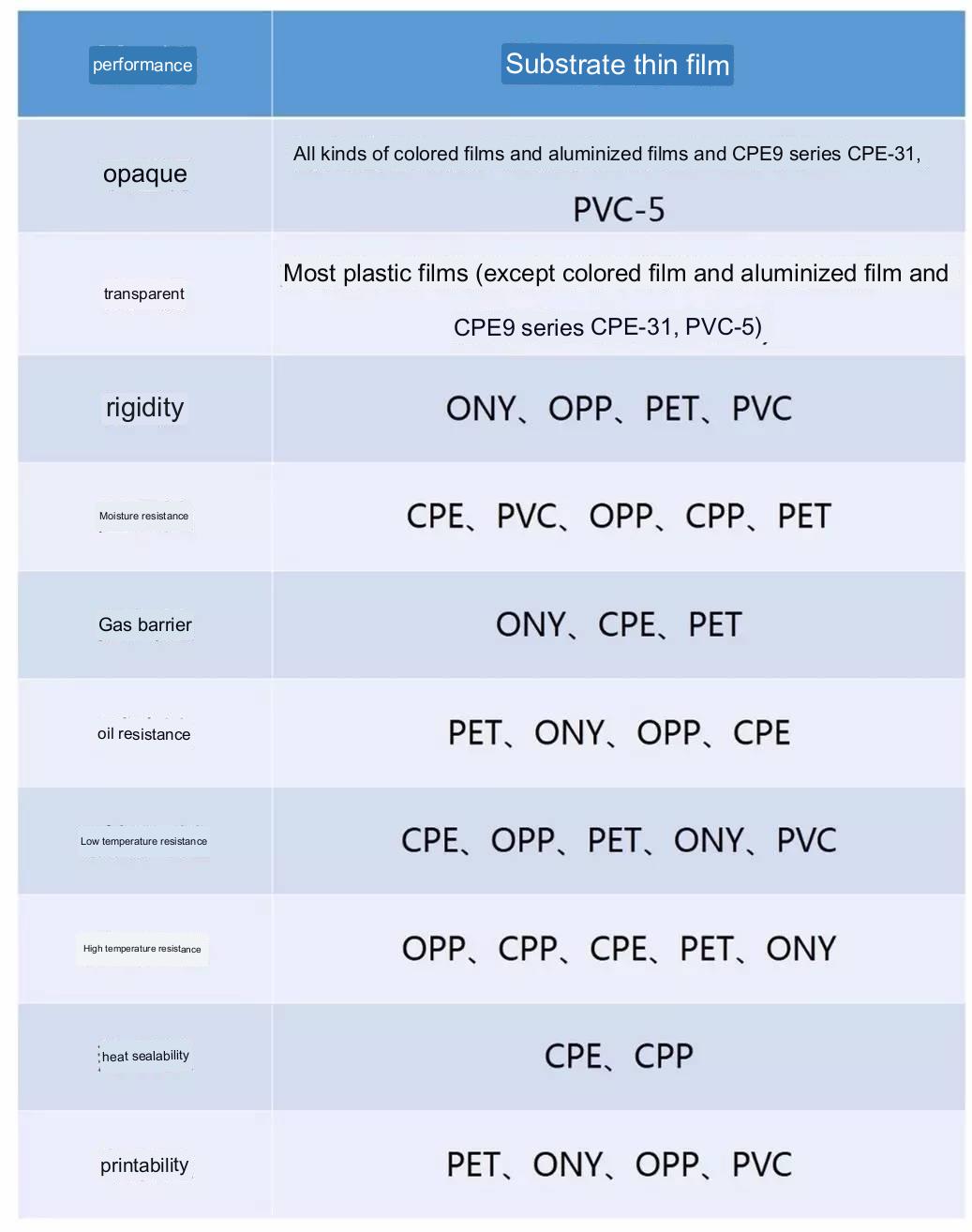

Izici zokusebenza zamafilimu amakhulu epulasitiki:

Ifilimu ye-Biaxially Oriented Polypropylene (BOPP)

I-Polypropylene iyi-resin ye-thermoplastic ekhiqizwa yi-polymerization ye-propylene. Izinto ze-Copolymer PP zinezinga lokushisa eliphansi lokuhlanekezela ukushisa (100°C), ukukhanya okuphansi, ukucwebezela okuphansi, nokuqina okuphansi, kodwa kunamandla omthelela anamandla, futhi amandla omthelela we-PP ayanda ngokunyuka kokuqukethwe kwe-ethylene . Izinga lokushisa le-Vicat elithambisayo le-PP lingu-150°C. Ngenxa yezinga eliphakeme le-crystallinity, le nto inokuqina okuhle kakhulu kwendawo kanye nezakhiwo zokumelana nokunwaya. I-PP ayinazo izinkinga zokuqhekeka kokucindezeleka kwemvelo.

Ifilimu ye-polypropylene ye-Biaxially oriented polypropylene (BOPP) iyimpahla yokupakisha eguquguqukayo esobala eyathuthukiswa ngeminyaka yawo-1960s. Isebenzisa umugqa wokukhiqiza okhethekile ukuxuba izinto ezingavuthiwe ze-polypropylene kanye nezithasiselo ezisebenzayo, zincibilike futhi zizixove zibe amashidi, bese zinwetshwa zibe amafilimu. Isetshenziswa kakhulu ekufakweni kokudla, uswidi, ugwayi, itiye, ijusi, ubisi, izindwangu, njll., futhi inedumela elithi "Packaging Queen". Ngaphezu kwalokho, ingasetshenziswa futhi ekulungiseleleni imikhiqizo yokusebenza enenani eliphakeme njenge-membrane kagesi nama-microporous membranes, ngakho-ke amathemba okuthuthukiswa kwamafilimu e-BOPP abanzi kakhulu.

Ifilimu ye-BOPP ayinayo kuphela izinzuzo zokuminyana okuphansi, ukumelana nokugqwala okuhle nokumelana nokushisa okuhle kwe-PP resin, kodwa futhi inezakhiwo ezinhle ze-optical, amandla aphezulu emishini kanye nemithombo ecebile yezinto zokusetshenziswa. Ifilimu ye-BOPP ingahlanganiswa nezinye izinto ezinezici ezikhethekile ukuze kuthuthukiswe noma kuthuthukiswe ukusebenza. Izinto ezisetshenziswa kakhulu zifaka ifilimu ye-PE, ifilimu ye-polypropylene (CPP), i-polyvinylidene chloride (PVDC), ifilimu ye-aluminium, njll.

Ifilimu ye-Low Density Polyethylene (LDPE)

Ifilimu ye-polyethylene, okungukuthi i-PE, inezici zokumelana nomswakama kanye nokungena komswakama okuphansi.

I-Low-density polyethylene (LPDE) iyi-resin yokwenziwa etholwe yi-ethylene radical polymerization ngaphansi kwengcindezi ephezulu, ngakho-ke ibizwa nangokuthi "i-polyethylene ephezulu yokucindezela". I-LPDE iyimolekyuli enamagatsha enamagatsha anobude obuhlukene ochungechungeni oluyinhloko, inamagatsha angaba ngu-15 kuya kwangu-30 e-ethyl, i-butyl noma amade ngama-athomu ekhabhoni ayi-1000 eketango eliyinhloko. Ngenxa yokuthi iketango lamangqamuzana liqukethe amaketanga amagatsha amade namafushane, umkhiqizo unokuminyana okuphansi, ukuthamba, ukumelana nokushisa okuphansi, ukumelana nomthelela omuhle, ukuqina okuhle kwamakhemikhali, futhi ngokuvamile ukumelana ne-asidi (ngaphandle kwama-acid oxidizing aqinile), i-Alkali, ukugqwala kukasawoti, kunokuhle. izakhiwo zokufaka ugesi kagesi. I-Translucent futhi icwebezelayo, inokuqina okuhle kakhulu kwamakhemikhali, ukuvaleka kokushisa, ukumelana namanzi nokumelana nomswakama, ukumelana nokubanda, futhi ingabiliswa. Ububi bayo obuyinhloko isithiyo sayo esimpofu emoyeni.

Ivamise ukusetshenziswa njengefilimu yongqimba yangaphakathi yezinto zokupakisha eziguquguqukayo eziyinhlanganisela, futhi iyifilimu yokupakisha esetshenziswa kakhulu futhi esetshenziswa kakhulu njengamanje, ibalwa ngaphezu kuka-40% wokusetshenziswa kwamafilimu okupakisha epulasitiki. Kunezinhlobo eziningi zamafilimu okupakisha e-polyethylene, futhi ukusebenza kwawo kuhlukile. Ukusebenza kwefilimu yongqimba olulodwa kukodwa, futhi ukusebenza kwefilimu eyinhlanganisela kuyahambisana. Yiyona nto eyinhloko yokupakishwa kokudla. Okwesibili, ifilimu ye-polyethylene nayo isetshenziswa emkhakheni wobunjiniyela bomphakathi, njenge-geomembrane. Isebenza njengengangeni manzi kwezobunjiniyela bomphakathi futhi inokungena okuphansi kakhulu. Ifilimu yezolimo isetshenziswa kwezolimo, engahlukaniswa ifilimu elichithiwe, ifilimu ye-mulch, ifilimu yekhava ebabayo, ifilimu yokugcina eluhlaza nokunye.

Ifilimu ye-polyester (PET)

Ifilimu ye-Polyester (PET), eyaziwa ngokuthi i-polyethylene terephthalate, ipulasitiki yobunjiniyela be-thermoplastic. Kuyinto yefilimu eyenziwe ngamashidi aminyene nge-extrusion bese yelulwa nge-biaxially. Ifilimu ye-polyester ibonakala ngezakhiwo ezinhle kakhulu zemishini, ukuqina okuphezulu, ubulukhuni nokuqina, ukumelana nokubhoboza, ukumelana nokungqubuzana, izinga lokushisa eliphezulu nokumelana nokushisa okuphansi, ukumelana namakhemikhali, ukumelana nowoyela, ukuqina komoya nokugcinwa kwephunga. Enye yezingxenye zefilimu eziyinhlanganisela yaphakade, kepha ukumelana ne-corona akukuhle.

Intengo yefilimu ye-polyester iphakeme kakhulu, futhi ukushuba kwayo ngokuvamile ku-0.12 mm. Ivame ukusetshenziswa njengempahla yangaphandle yokupakishwa kokudla ukuze kufakwe, futhi inokuphrinta okuhle. Ngaphezu kwalokho, ifilimu ye-polyester ivame ukusetshenziswa njengokuphrinta nokupakisha okusebenzisekayo njengefilimu yokuvikela imvelo, ifilimu ye-PET, nefilimu emhlophe emhlophe, futhi isetshenziswa kabanzi ezimbonini ezifana namapulasitiki aqiniswe nge-glass fiber, izinto zokwakha, ukuphrinta, nemithi kanye nempilo.

Ifilimu yepulasitiki enayiloni (ONY)

Igama lekhemikhali lenayiloni yi-polyamide (PA). Njengamanje, kunezinhlobo eziningi zenayiloni ezikhiqizwa yizimboni, futhi izinhlobo eziyinhloko ezisetshenziselwa ukukhiqiza amafilimu inayiloni 6, inayiloni 12, inayiloni 66, njll. amandla aqinile, nokumelana nokushisa okuhle, ukumelana nokubanda, ukumelana nowoyela kanye nokumelana ne-organic solvent. Ukumelana nokugqokwa okuhle kakhulu nokumelana nokubhoboza, okuthambile, okuhle kakhulu, izakhiwo ezinhle kakhulu zokuthibela umoya-mpilo, kepha izakhiwo ezingezinhle zokuthibela umhwamuko wamanzi, ukumuncwa komswakama ophezulu kanye nokungena umswakama, ukwehla kokushisa okungekuhle, kulungele ukupakisha izinto ezinzima, njengokudla kocansi okunamafutha, imikhiqizo yenyama, ethosiwe. ukudla, ukudla okufakwe ivacuum, ukudla okuphekwe ngesitimu, njll.

Ifilimu ye-Cast Polypropylene (CPP)

Ngokungafani nenqubo yefilimu ye-polypropylene (BOPP) ye-biaxially oriented, ifilimu ye-polypropylene eyi-cast (CPP) iyifilimu ye-flat extrusion enganwetshiwe, engaqondile ekhiqizwa ngokuncibilika nokucisha. Ibonakala ngesivinini sokukhiqiza esisheshayo, ukuphuma okuphezulu, ukubonakala okuhle kwefilimu, isicwebezelisi, ukufana kokuqina, nokulinganisela okuhle kakhulu kwezakhiwo ezahlukahlukene. Ngenxa yokuthi iyifilimu eyisicaba ekhishwe, umsebenzi wokulandelela njengokuphrinta nokuhlanganisa kulula kakhulu. I-CPP isetshenziswa kakhulu ekufakweni kwezindwangu, izimbali, ukudla, kanye nezidingo zansuku zonke.

Ifilimu yepulasitiki ehlanganiswe ne-aluminium

Ifilimu eyenziwe nge-aluminum inazo zombili izici zefilimu yepulasitiki kanye nezici zensimbi. Indima ye-aluminium plating ebusweni befilimu ukuvikela ukukhanya nokuvimbela imisebe ye-ultraviolet, engagcini nje ukwandisa isikhathi sokuphila kokuqukethwe, kodwa futhi ithuthukisa ukukhanya kwefilimu. Ngakho-ke, ifilimu eyenziwe nge-aluminium isetshenziswa kakhulu emaphaketheni ayinhlanganisela, ikakhulukazi asetshenziswa emaphaketheni okudla okomile nokukhukhumele njengamabhisikidi, kanye nokupakishwa kwangaphandle kweminye imithi nezimonyo.

Isikhathi sokuthumela: Jul-19-2023